Application of clinch

Application of clinch

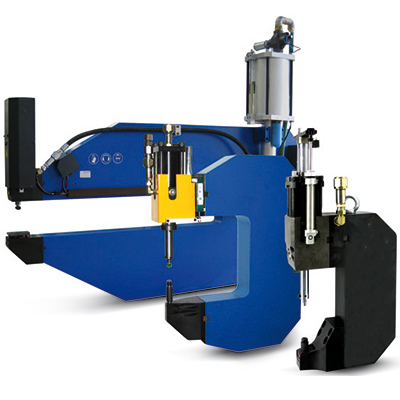

Clinching is a circular, leak proof joint formed by drawing the metals into a circulate “cup” and then expanding the diameter to form a 360° radial lock below the bottom sheet.

Clinching system joins sheet metals, extrusions and formed metal components. Steel, aluminum, brass and other metals can be joined, including coated and painted stock,. Thickness ranging from ( 2) layers x 0.2 mm up to a combined total thickness of 8 mm ( 320 “) can be joined with readily available standard tooling.

The metals are joined by a local deformation which creates a strong leak proof interlock. Simple mechanical punch and die tooling is used to produce the joint.

World Wide Use in:

- APPLIANCES

- ELECTRONICS

- AUTOMOBILES

- STEEL FRAME HOUSING

- AND OTHER PRODUCTS

Application examples of ESP clinching

1-Sheet-metalworking Industry

- Shelving

- Lights

- Drawers

- Traffic signs

- Light shafts

- While goods

- Window frames

- Computer housings

- Control cabinets

- Industrial doors

- Sound proofing walls

2-Automotive industry

- Wings

- Doors

- Front bonnets

- Rear bonnets

- Steering column brackets

3-Heating, AirConditioning, Ventilation

- Filter units

- Heat exchangers

- Ventilator housings

4-Automotive Supply Industry

- Tank contacts

- Brake pedals

- Seat frames

- Mirror housings

- Windscreen Wiper motors, suspension

Samples:

Leave a Reply

Want to join the discussion?Feel free to contribute!